Earring

1999 (made)

| Artist/Maker | |

| Place of origin |

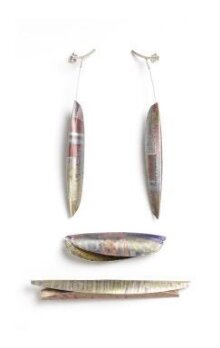

Jane Adam's jewellery shows the extraordinary versatility of aluminium. Her extensive research into the properties of this metal and her fine appreciation of colour and line combine in the subtle colours and shimmering textures achieved in these earrings.

To create this effect the aluminium is first anodised by immersing it in a solution of sulphuric acid and water then passing an electric current through it. This forms a thin surface film of aluminium oxide which is very tough yet has microscopic pores which enable colouring dyes to be absorbed. After dying the surface is sealed. Shapes for jewellery are cut from the dyed and sealed sheet, and these are then compressed in a rolling mill, adding texture or crazing to the surface. As anodised aluminium cannot be soldered the assembling of a piece often requires the addition of minimal wires and findings to the design.

To create this effect the aluminium is first anodised by immersing it in a solution of sulphuric acid and water then passing an electric current through it. This forms a thin surface film of aluminium oxide which is very tough yet has microscopic pores which enable colouring dyes to be absorbed. After dying the surface is sealed. Shapes for jewellery are cut from the dyed and sealed sheet, and these are then compressed in a rolling mill, adding texture or crazing to the surface. As anodised aluminium cannot be soldered the assembling of a piece often requires the addition of minimal wires and findings to the design.

Object details

| Categories | |

| Object type | |

| Parts | This object consists of 2 parts.

|

| Materials and techniques | Anodised, dyed and crazed aluminium, gold and stainless steel wire |

| Brief description | Pair of earrings made from dyed, anodised and crazed aluminium, gold and stainless steel wire. Designed and made by Jane Adam, England, London, 1999. |

| Physical description | Long, narrow pods of folded-over anodised aluminium that has been dyed and crazed in an abstract pattern in red, ochre and blue. The edges of the pods are left slightly open to reveal the inner surface of gold leaf. The pods each hang from a steel wire and a silver twig-like fixing. |

| Credit line | Given in honour of Elizabeth Goring |

| Summary | Jane Adam's jewellery shows the extraordinary versatility of aluminium. Her extensive research into the properties of this metal and her fine appreciation of colour and line combine in the subtle colours and shimmering textures achieved in these earrings. To create this effect the aluminium is first anodised by immersing it in a solution of sulphuric acid and water then passing an electric current through it. This forms a thin surface film of aluminium oxide which is very tough yet has microscopic pores which enable colouring dyes to be absorbed. After dying the surface is sealed. Shapes for jewellery are cut from the dyed and sealed sheet, and these are then compressed in a rolling mill, adding texture or crazing to the surface. As anodised aluminium cannot be soldered the assembling of a piece often requires the addition of minimal wires and findings to the design. |

| Collection | |

| Accession number | M.16:1, 2-2008 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | May 8, 2008 |

| Record URL |

Download as: JSON